Products

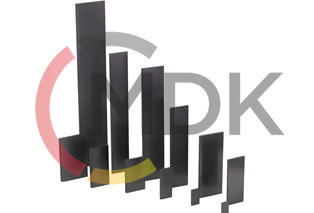

Carbon Vanes For Vacuum Pumps

We manufacture carbon vanes for dry running oil-free pumps and compressors with our special carbon graphite material.

Our products are perfectly compatible with BECKER, RIETSCHLE, BUSH, ORION and DVP pumps.

Distinguishing features of our MDK carbon vanes from others;

Wear Duration

Our products imported from Germany have an average of 3 times longer wear life compared to cheap, low-quality carbon vanes.

Maintenance Cost

The products manufactured and sold by our company have a minimum dusting performance exhibiting formula specially developed for vacuum pump vanes.

Low quality, inexpensive carbon vanes have a higher wear rate. This will increase the dust in your filters and will cause you to change your filter more often. Therefore your maintenance costs will increase.

Operating temperature

The carbon vanes manufactured by our company provide optimal working conditions.

Materials that use low graphite grades or that are recycled into carbon vanes after being used in different industrial applications cause temperature increases up to +20°C at the operating temperature of your pump.

With the effect of high temperature over time, even the grease in the bearings is affected and creates extra maintenance costs.

Flexibility

Flexibility is one of the most important factors for smooth sliding of the carbon vanes on the stator. Hard graphites cause premature wear on the stator.

Thanks to our raw material with a specially developed formula for vacuum pump carbons, the wear effect of our products on the stator surface is minimized.

Productivity

In order to obtain maximum efficiency from our products, our company manufactures in accordance with the DIN 7168 production tolerances of the German Standards Institute (Deutsches Institut für Normung). Tolerances are important in the production of vanes used in vacuum pumps. In large-scale productions, the carbon vanes break and/or deteriorate. If the dimensions are manufactured smaller than they should be, it causes a decrease in pump performance and vacuum loss.

Pump Life

Carbon vanes using low graphite grades or made of hard graphite have a high risk of breakage. Broken hard graphite particles cause scratches on rotor and stator surfaces and permanent damage to the pump. This will shorten the economic life of your pump.